Chinese scientists develop enzyme for tenfold improvement in PU plastic degradation

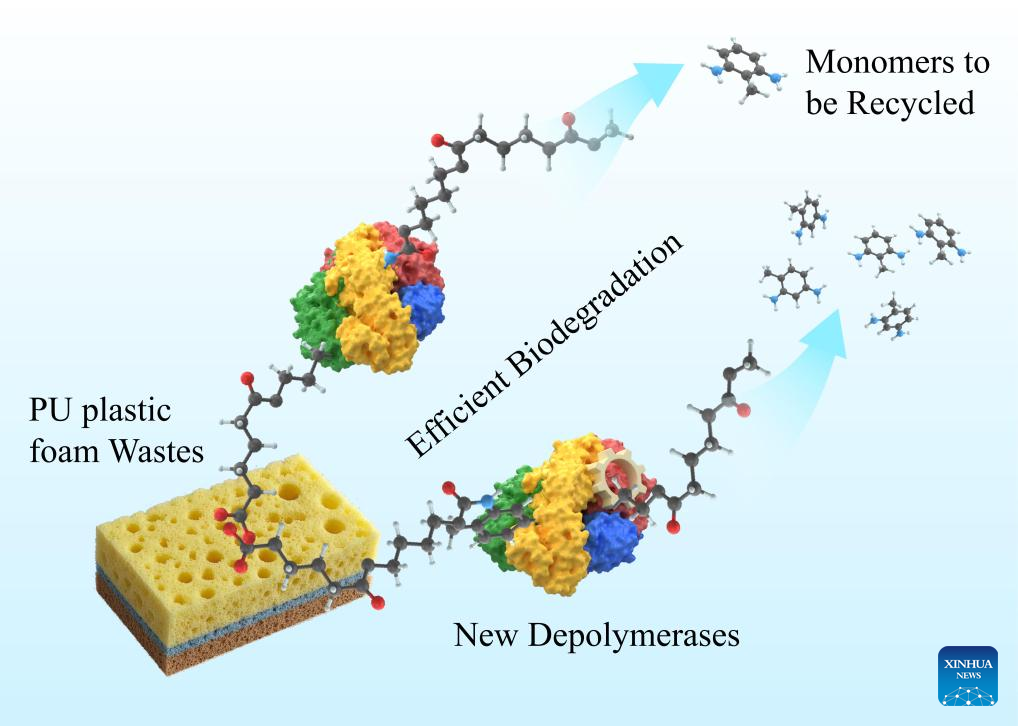

This schematic diagram shows a new variant of polyurethane (PU) plastic-degrading enzyme developed by a Chinese research team degrading the PU plastic foam wastes. A Chinese research team has made a promising advancement in managing waste plastic and promoting recycling, which remain a global challenge. Researchers from the Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences, recently developed a new variant of polyurethane (PU) plastic-degrading enzyme, achieving a more than tenfold increase in PU plastic degradation efficiency. (Xinhua)

TIANJIN, July 12 (Xinhua) -- A Chinese research team has made a promising advancement in managing waste plastic and promoting recycling, which remain a global challenge.

Researchers from the Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences, recently developed a new variant of polyurethane (PU) plastic-degrading enzyme, achieving a more than tenfold increase in PU plastic degradation efficiency.

Biological degradation methods, which employ enzymes to accelerate chemical reactions, are a key focus in international plastic waste research. These methods are preferred over traditional chemical degradation due to their lower energy consumption and reduced pollution.

However, PU plastic -- commonly used in insulation foam, car seat cushions and other daily products -- are more difficult to degrade through biological methods due to their complex chemical bonds.

Based on cooperative research with German scientists about the structure-function relationship of PU plastic-degrading enzymes, the Chinese researchers identified a new PU depolymerase from nature and further engineered its structure to create a variant with significantly enhanced performance.

This "artificial enzyme" degraded PU plastic nearly 11 times faster than the wild type, greatly improving the PU plastic waste recycling potential.

The findings were published in the journals Advanced Science and ACS Catalysis.

According to the UN Environment Programme, over 400 million tonnes of plastic are produced annually, with less than 10 percent recycled.

This breakthrough offers a promising tool for large-scale PU bio-recycling and a sustainable solution for plastic waste. "After enzymatic breakdown, waste plastic is converted into monomers that can be reused in plastic production," explained Liu Weidong, a researcher at the institute.

"Next, we will advance the industrial application of enzyme preparations," Liu added.

Photos

Related Stories

- Chinese scientists develop novel "marshmallow" concrete to gently stop aircraft during emergency landings

- Pioneering Chinese scientists shaping future of 2D metal research

- Chinese scientists introduce new bio-based nanocomposite, green alternative to traditional plastics

- Chinese scientists develop controllable chiral graphene rolls for spintronics

- China's steel giant develops low temperature resistant, durable steel plate

Copyright © 2025 People's Daily Online. All Rights Reserved.